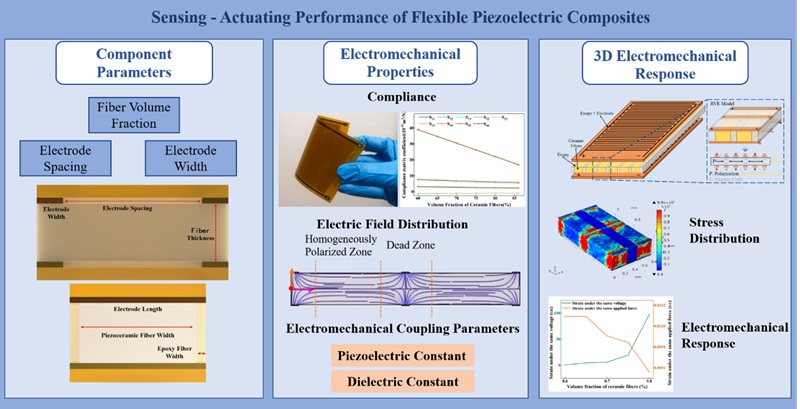

1. Introduction

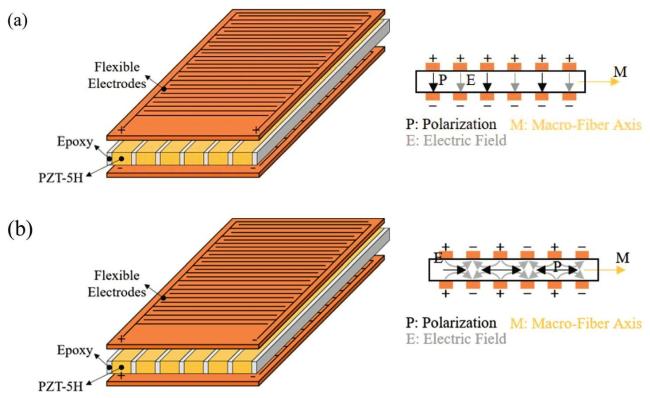

Fig. 1. A schematic diagram of an FPC structure. (a) D31-FPC. (b) D33-FPC. |

2. Establishment of the finite element model for FPC at the mesoscopic scale

2.1. Modeling principle of the RVE (representative volume element)

Table 1 Geometrical parameters of RVE model components. |

| Components | Physical quantities | Symbols | Values |

|---|---|---|---|

| Piezoceramic fiber | Fiber width (mm) | Wf | 0.3 |

| Fiber spacing (mm) | Sf | 0.2 | |

| Fiber thickness (mm) | Hf | 0.3 | |

| Epoxy resin | Fiber width (mm) | Wi | 0.2 |

| Interdigitated electrodes | Finger center to center spacing (mm) | Si | 0.65 |

| Finger thickness | Hi | 0.01 |

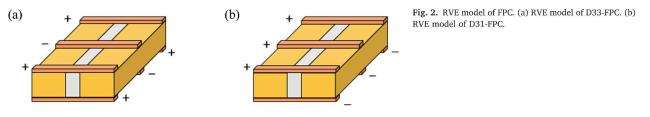

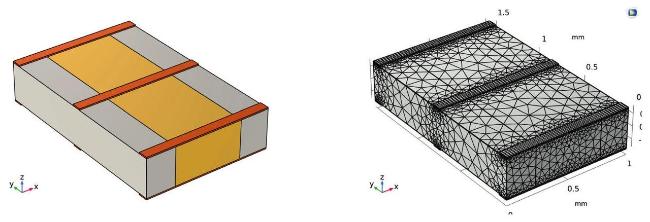

2.2. Establishment of the RVE model

Fig. 2. RVE model of FPC.(a)RVE model of D33-FPC.(b)RVE model of D31-FPC. |

Table 2 Material properties of RVE components. |

| Components | PZT-5H | Epoxy resin | Copper |

|---|---|---|---|

| Young's modulus (GPa) | | 2.9 | 117.2 |

| Shear modulus (GPa) | | 1.11 | 43.41 |

| Poisson's ratio | | 0.3 | 0.35 |

| Piezoelectric constant (pC/N) | | - | - |

| Dielectric constant ( nF/m ) | | 0.0376 | 0.0443 |

Table 3 RVE model parameters for different PZT volume fractions. |

| PZT Volume Fractions | Model width (mm) | PZT fiber width (mm) | Epoxy resin fiber width (mm) |

|---|---|---|---|

| 60 % | 1 | 3/7 | 2/7 |

| 65 % | 1 | 13/27 | 7/27 |

| 70 % | 1 | 7/13 | 3/13 |

| 75 % | 1 | 3/5 | 2/5 |

| 80 % | 1 | 2/3 | 1/6 |

3. Influence of fiber volume fraction on the electromechanical

3.1. Influence of fiber volume fraction on D33-FPC performance

3.2. Influence of fiber volume fraction on D33-FPC performance

Fig. 3. (a)RVE model. (b) mesh scheme. |

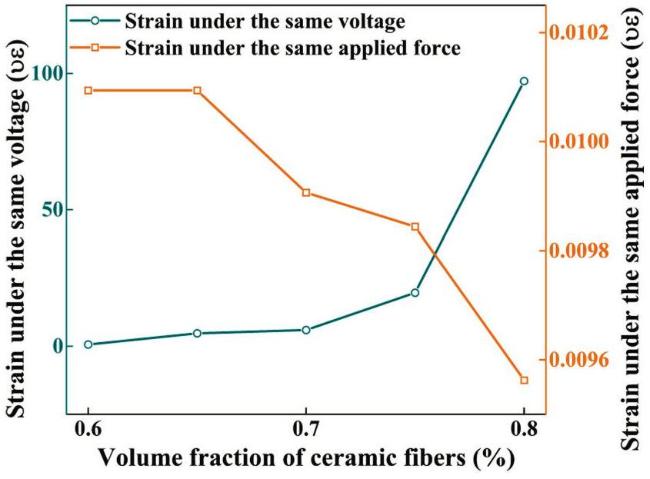

Fig. 4. Variation of strain with fiber volume fraction for D33-RVE under the same electromechanical conditions. |

3.3. Influence of fiber volume fraction on D31-FPC performance

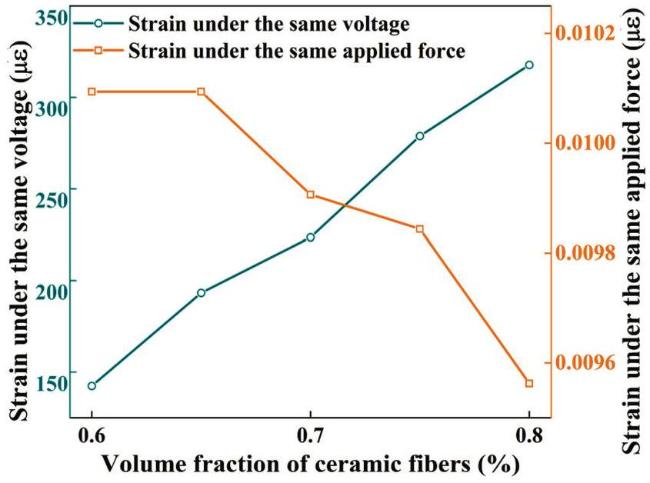

Fig. 5. Variation of strain with fiber volume fraction for D31-RVE under the same electromechanical conditions. |

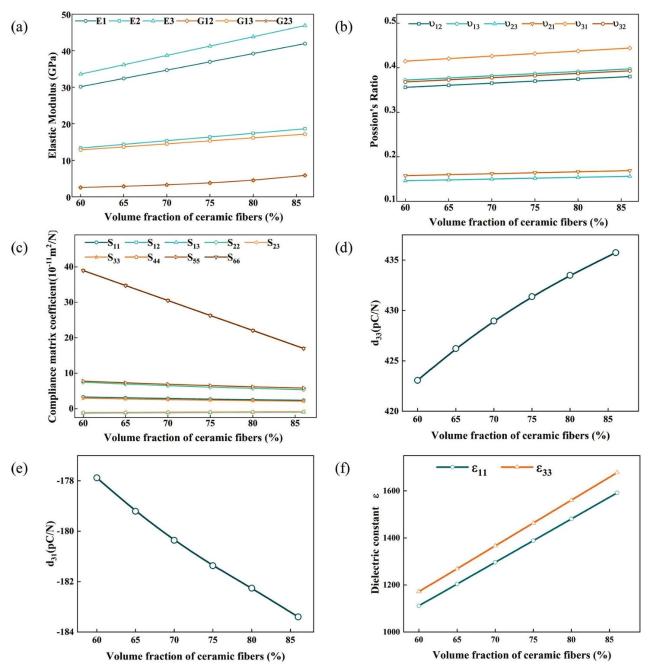

3.4. Influence of fiber volume fraction on the electromechanical coupling parameters of D33-FPC and D31-FPC

4. Influence of electrode geometrical parameters on the electromechanical properties of FPC

4.1. Electric field distribution in D33-FPC and D31-FPC

4.1.1. Electric field distribution in D33-FPC

Fig. 6. (a) Effect of ceramic fiber volume fraction on the elastic modulus of the piezoelectric active layer. (b) Effect of ceramic fiber volume fraction on the Possion's Ratio of the piezoelectric active layer. (c) Effect of ceramic fiber volume fraction on the compliance of the piezoelectric active layer. (d) Effect of ceramic fiber volume fraction on the piezoelectric constant d33 of the piezoelectric active layer. (e) Effect of ceramic fiber volume fraction on the piezoelectric constant d31 of the piezoelectric active layer. (f) Effect of ceramic fiber volume fraction on the Dielectric Constant of the piezoelectric active layer. |

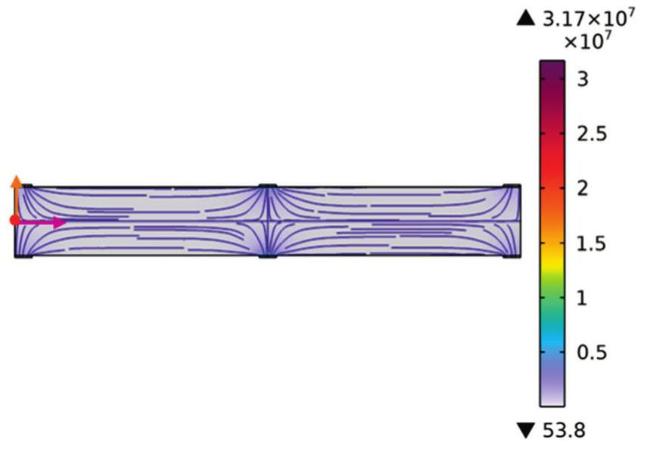

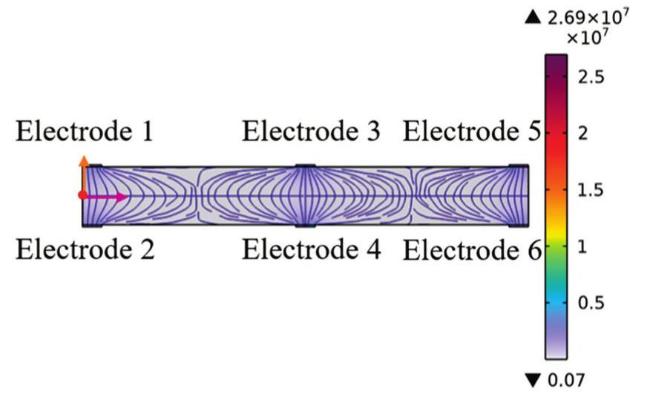

Fig. 7. Electric field distribution in the yOz plane of the RVE model for D33FPC. |

Fig. 8. Electric field distribution in the yOz plane of the RVE model for D31FPC. |

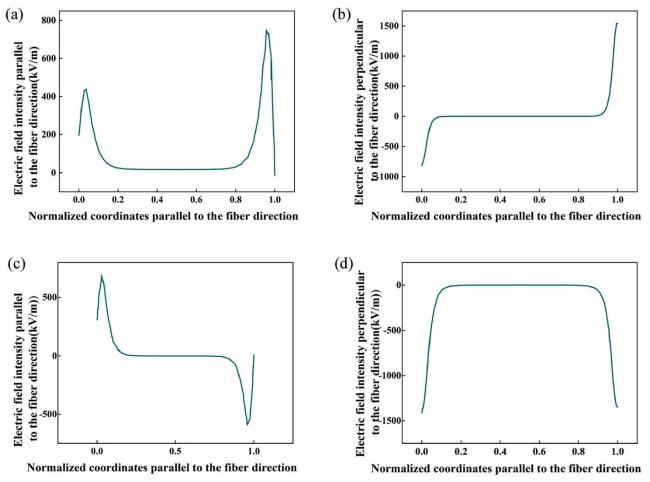

Fig. 9. (a) Electric field intensity parallel to the fiber direction for D33-Type FPC; (b) Electric field intensity perpendicular to the fiber direction for D33-Type FPC; (c) Electric field intensity parallel to the fiber direction for D31-Type FPC; (d) Electric field intensity perpendicular to the fiber direction for D31-Type FPC. |

4.1.2. Electric field distribution in D31-FPC

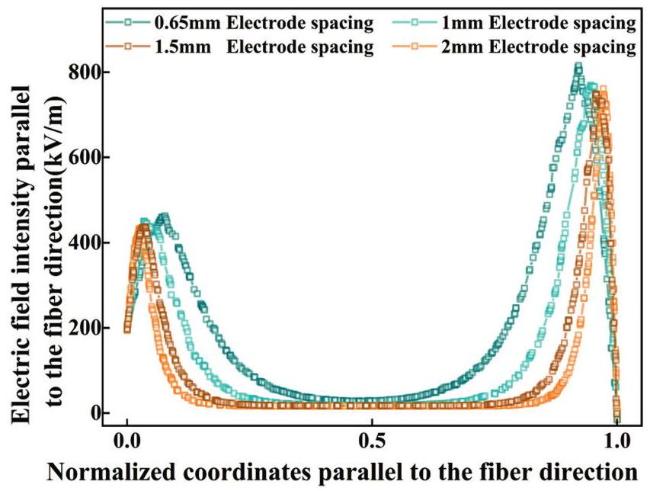

4.1.3. Effect of interdigital electrode spacing on the performance of D33-FPC

between adjacent electrodes is normalized. The horizontal axis represents the distance from the point of interest to the midline of the electrode in the fiber direction, normalized by the electrode spacing. This ratio, ranging from 0 to 1, reflects the position of the point of interest relative to the reference electrode midline along the fiber direction.

Fig. 10. Distribution of the electric field component perpendicular to the fiber direction between electrodes for D33-type FPC (the horizontal axis representing the normalized coordinate parallel to the electric field direction, i.e., the ratio of the distance from the observation point to the electrode centerline to the electrode spacing). |

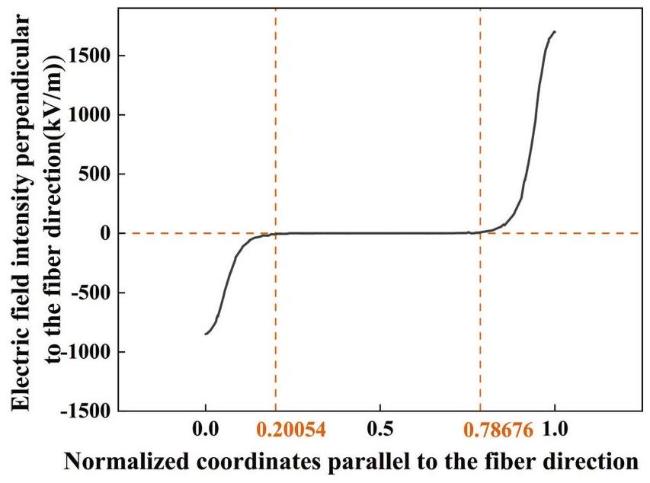

Fig. 11. Effect of electrode spacing on the electric field intensity perpendicular to the fiber direction for D33-FPC. |

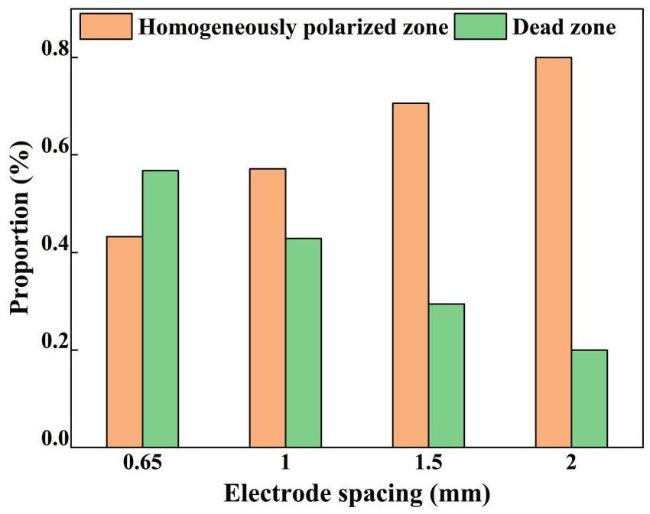

Table 4 Effect of electrode spacing on the proportions of homogeneously polarization zone and dead zone in D33-FPC. |

| Electrode spacing (mm) | 0.65 | 1 | 1.5 | 2 |

|---|---|---|---|---|

| Homogeneously polarization zone | 43.249% | 57.106% | 70.586% | 79.995% |

| Dead zone | 56.751% | 42.894% | 29.414% | 20.005% |

Fig. 12. Effect of electrode spacing on the electric field distribution region for D33-FPC. |

Fig. 13. Effect of electrode spacing on the electric field intensity parallel to the fiber direction for D33-FPC. |

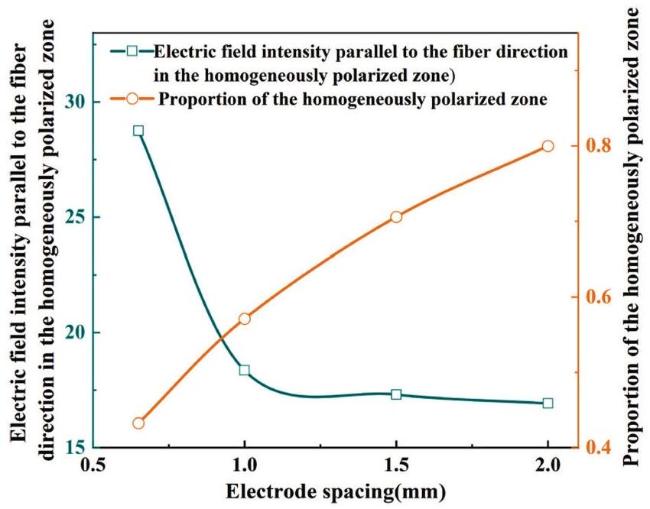

Fig. 14. Variation trend of the applied electric field intensity and effective electric field area ratio with electrode spacing in D33-FPC. |

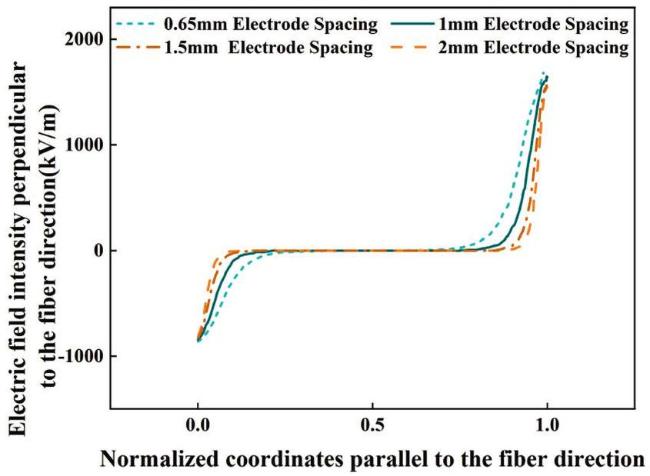

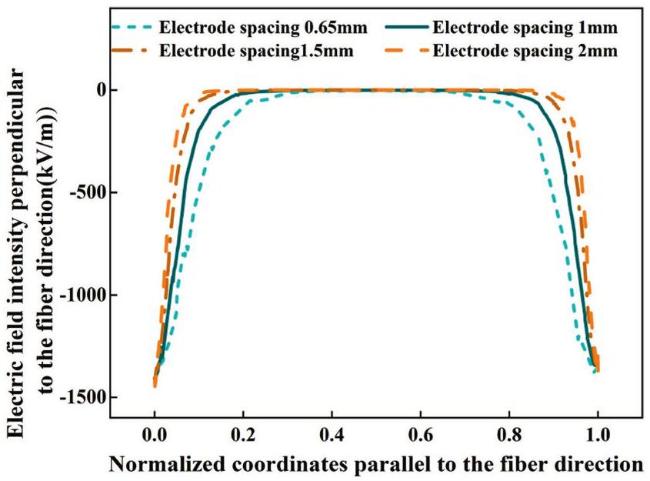

Fig. 15. Effect of electrode spacing on the electric field distribution perpendicular to the fiber direction for D31-FPC. |

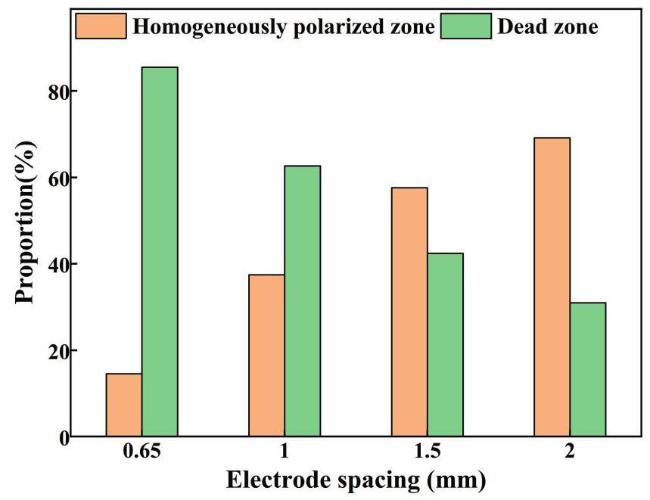

4.1.4. Effect of interdigital electrode spacing on the performance of D31FPC

Table 5 Effect of electrode spacing on the proportions of homogeneously polarization zone and dead zone in D31-FPC. |

| Electro spacing (mm) | 0.65 | 1 | 1.5 | 2 |

|---|---|---|---|---|

| Homogeneously polarization zone | 14.541 % | 37.431 % | 57.618 % | 69.081 % |

| Dead zone | 85.459 % | 62.569 % | 42.382 % | 30.919 % |

Fig. 16. Effect of electrode spacing on the electric field distribution region for D31-FPC. |

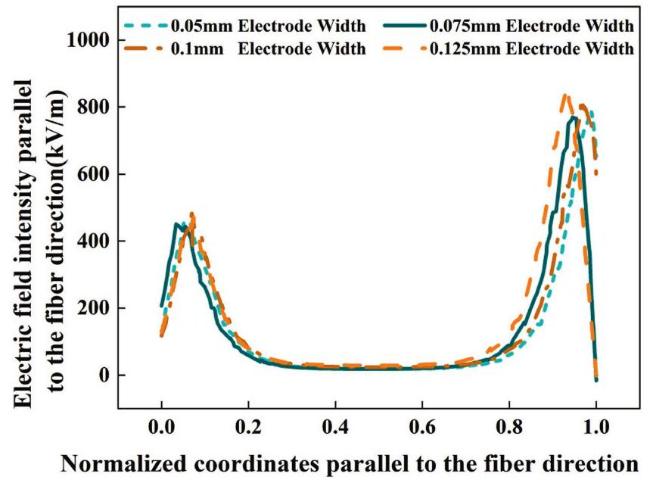

Fig. 17. Effect of electrode width on the electric field intensity parallel to the fiber direction for D33-Type FPC. |

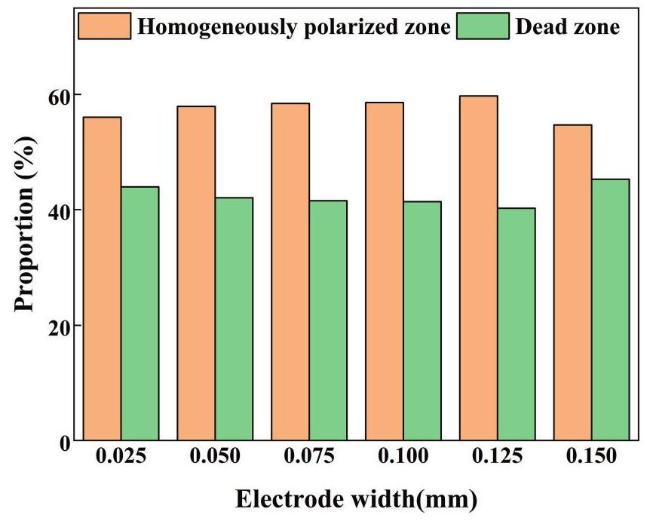

4.2. Effect of interdigital electrode width on the performance of two different types of FPC

4.2.1. Effect of interdigital electrode width on the performance of D33-FPC

Table 6 Effect of electrode width on the proportions of homogeneously polarization zone and dead zone in D33-FPC. |

| Electrode width (mm) | 0.025 | 0.050 | 0.075 | 0.100 | 0.125 | 0.150 |

|---|---|---|---|---|---|---|

| Homogeneously polarization zone | 56.045 % | 57.926 % | 58.440 % | 58.610 % | 59.740 % | 54.710 % |

| Dead zone | 43.955 % | 42.074 % | 41.560 % | 41.390 % | 40.260 % | 45.290 % |

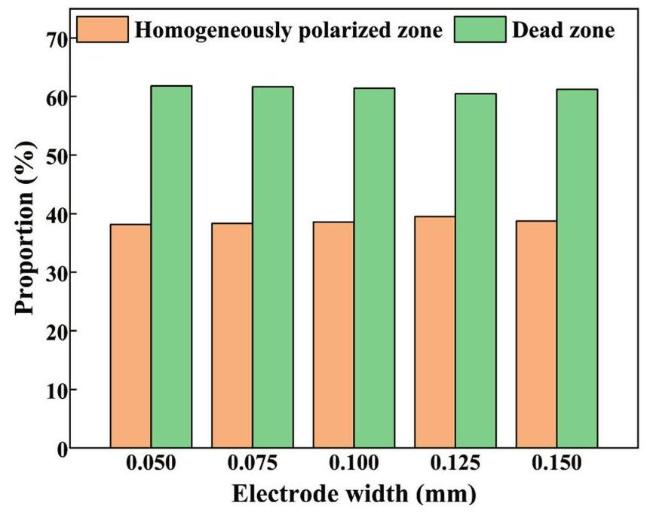

Table 7 Effect of Electrode Width on The Proportions of Homogeneously Polarization Zone and Dead Zone in D31-FPC. |

| Electrode Width (mm) | 0.050 | 0.075 | 0.100 | 0.125 | 0.150 |

|---|---|---|---|---|---|

| Homogeneously polarization zone | 38.184 % | 38.356 % | 38.598 % | 39.519 % | 38.766 % |

| Dead zone | 61.816 % | 61.644 % | 61.405 % | 60.481 % | 61.234 % |

Fig. 18. Effect of electrode width on the electric field distribution region for D33-Type FPC. |

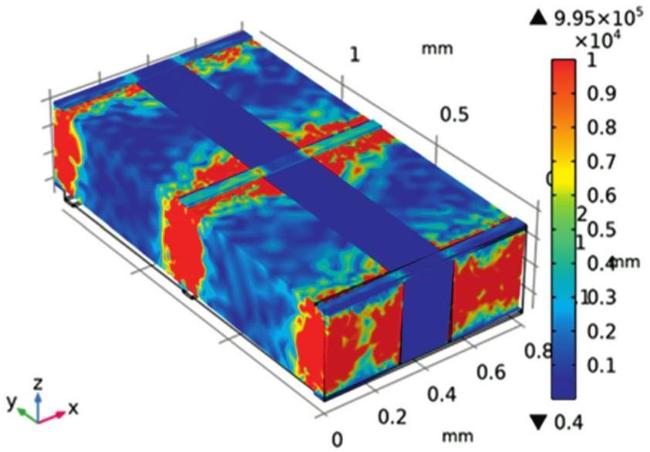

Fig. 19. Stress distribution of the RVE model of D33-FPC under 400 V voltage. |

4.2.2. Effect of interdigital electrode width on D31-FPC performance

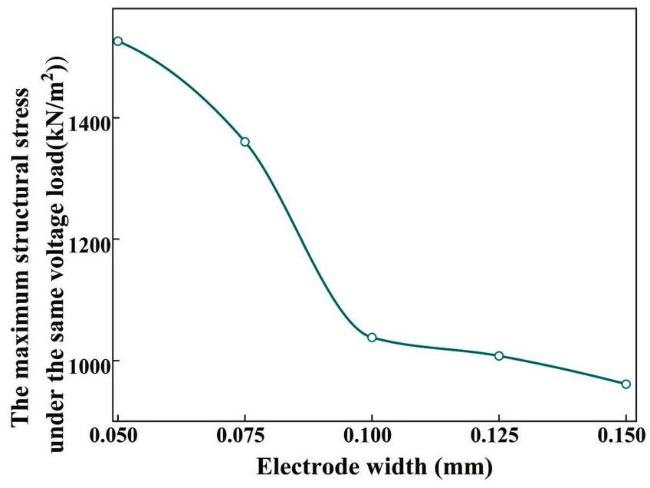

Fig. 20. Effect of electrode width on the maximum stress in D33-FPC. |

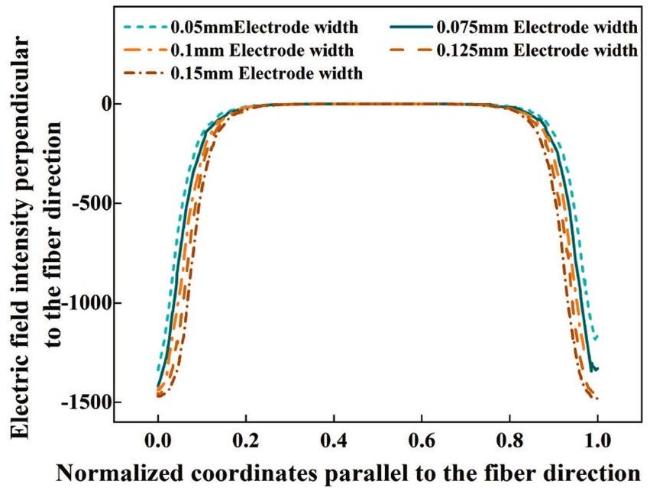

Fig. 21. Effect of electrode width on the electric field distribution perpendicular to the fiber direction for D31-FPC. |

Fig. 22. Effect of electrode width on the electric field distribution region for D31-FPC. |

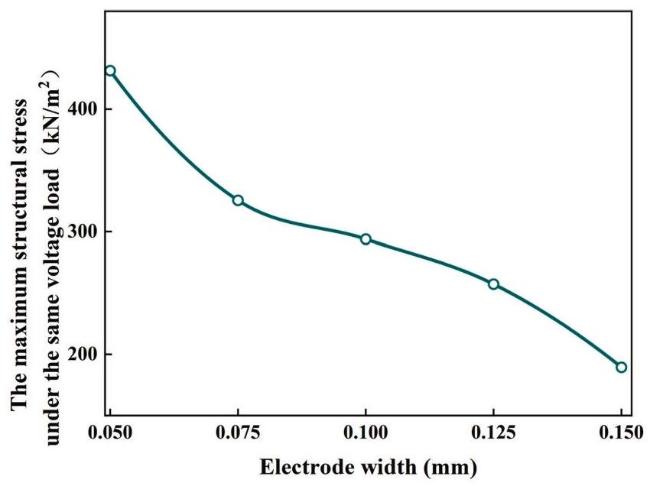

Fig. 23. Effect of electrode width on the maximum stress in D31-FPC. |